Transform Your Ceilings, Cladding, Facades and Large Format Tile Installs with 2D/3D Digital Templating

Precision and speed for high-impact finishing trades.

In ceilings, claddings, facades and large format tiles, small errors become big problems fast. A few millimetres out at set-out can turn into rework, delays, cracked tiles, misaligned rails, or panels that just don’t sit right.

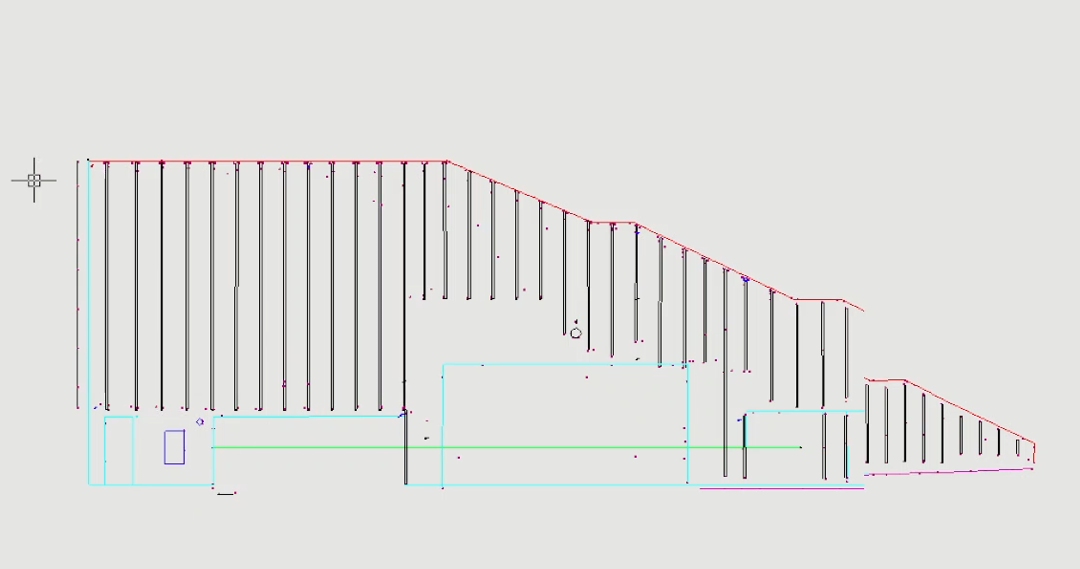

That’s where 2D/3D digital templating helps. We capture accurate on-site geometry and critical set-out details, then deliver clean CAD-ready outputs so your team can fabricate, plan, and install with confidence.

This replaces guesswork and patch-up measuring with a repeatable process that saves time, reduces risk, and makes you look sharp in front of builders and project managers.

Why digital templating is a game changer for facades, cladding, ceilings and large format tiles

If you’re doing anything curved, stepped, out-of-square, multi-level, or time-critical, digital templating stops problems before they hit the workshop or the site.

Accurate site geometry captured once, properly, on site

Faster set-out and planning, with fewer “we’ll make it work” moments

Reduced rework and wastage from incorrect assumptions

Better coordination around penetrations, edges, junctions, returns, and interfaces

Cleaner handover between site, CAD, fabrication, and install teams

Confidence to take on more complex work without slowing the whole job down

If you’ve ever had to re-cut, re-drill, or re-align because the building isn’t square (and it never is), this is the fix.

Where this helps most

Ceilings

ceiling rafts and feature ceilings

bulkheads and stepped soffits

acoustic panels and ceiling grids

set-out around services, lights, sprinklers, diffusers and access hatches

Facades

complex facade geometry and interface points

curved or angled features

bracket locations, reference points and set-out lines

multi-level alignment and consistency checks

Cladding

interior wall linings and sheet systems

rainscreen layouts and panelised cladding

junctions, corners, returns and reveals

openings, nibs, penetrations, and terminations

Large format tiles

wall and floor tile set-out for large formats

steps, landings, thresholds and transitions

niches, rebates, and penetrations

alignment planning to reduce skinny cuts and ugly outcomes

We measure and deliver accurate site geometry and reference data. If you need fully design-complete or “cut-ready” fabrication files, that depends on your system rules, product specs, fixing method, and design decisions. If those rules are defined, we can work with your team (or your drafter) to help you get to the right outcome.

How 2D/3D templating works

Step 1: Pre-check and scope

You send plans (or we review on a quick call). We confirm what matters: surfaces, interfaces, tolerances, penetrations, and what outputs your team needs.

Step 2: On-site capture

We capture the real-world geometry on site using digital measuring technology designed for construction and fabrication environments. This is where we lock in accuracy and remove assumptions.

Step 3: CAD output and handover

You receive CAD-ready files that reflect what’s actually on site. We can include reference lines, key points, and layers to suit your workflow.

Step 4: Install confidence

Your team installs with fewer surprises because the job has been measured properly and communicated clearly.

What you receive (typical deliverables)

Depending on what you need, you can receive:

2D CAD geometry (as-built / outer-edge / reference linework)

3D capture outputs for complex surfaces

layered CAD files for set-out points, reference lines, penetrations, openings, and notes

clear “what we measured” handover notes, so your installer and your CAD person are on the same page

Book Our Team for Professional Templating and Specialized Training

Take your balustrade and handrail installations to the next level with 2D/3D templating technology.

Our experienced team is ready to perform the templating for you, ensuring every measurement is accurate and that your installation goes smoothly.

Book a Templating Appointment: Let our experts handle the templating for your next project, saving you time and reducing costly reworks

Specialized Training: Receive training specific to your industry needs, empowering your team to use the templating system effectively.

Find the Right Templater for Your Business: Unsure which templater suits your business best? We can guide you in selecting the perfect solution tailored to your needs.

Ready to get started?

To learn more about how we can help you integrate digital templating into your operations.

Get in touch today!

Book a Template to get started and discover how 2D/3D measuring can enhance your Fit-out installations.